Definition

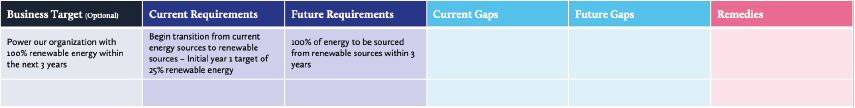

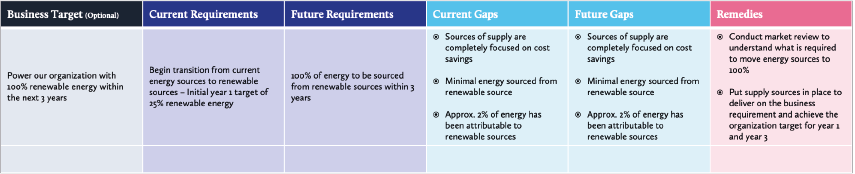

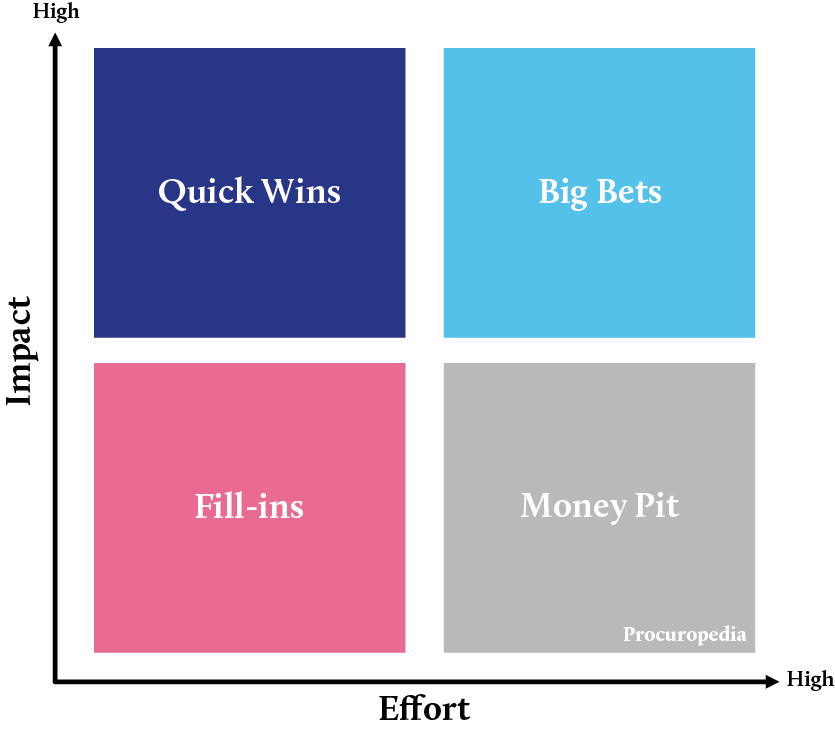

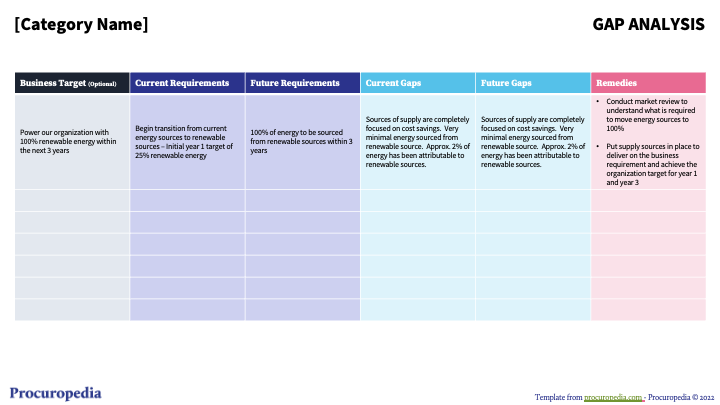

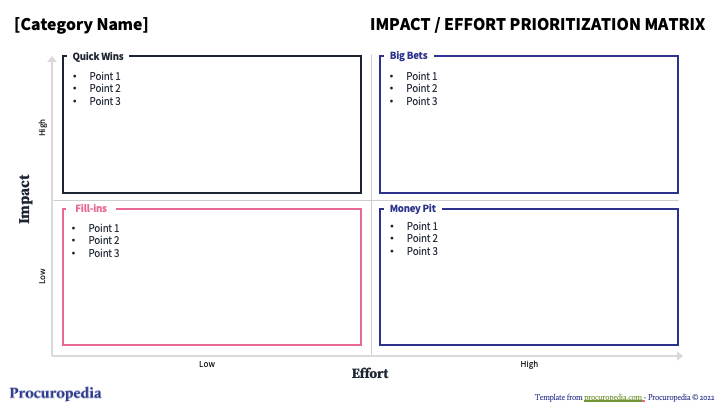

A Gap analysis is the process of assessing desired business targets and performance against current performance. In a procurement setting, the analysis can be used to assess the current and future business requirements against the current goods, services and capabilities available from the current supply base. The resulting gaps can then prioritized to close the most important gaps first.

Templates

Need more help? Have a request? Please drop us a line...